Fault Diagnosis and Elimination of Pipe Jacking Machine

Release time:

2020-09-29

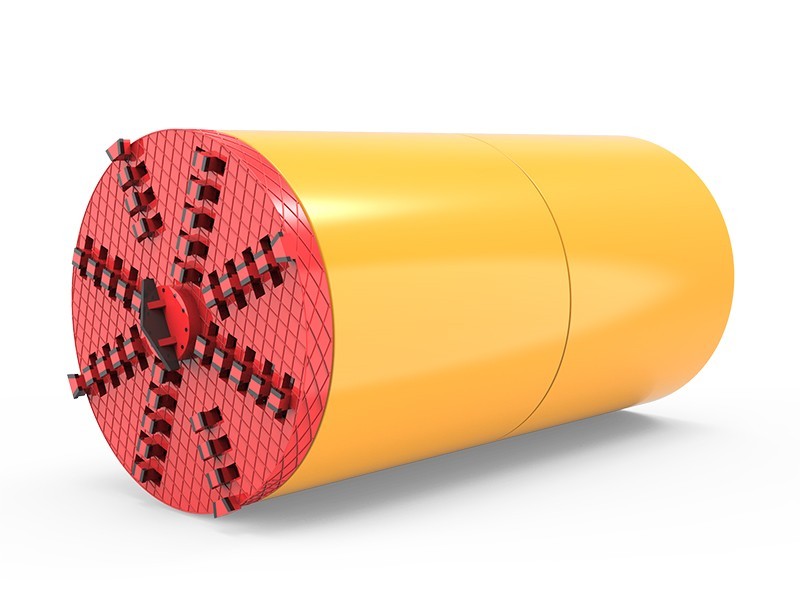

A Φ1 800 mm muddy water pressurized pipe jacking machine (expandable to 2000mm), the total length of the rotary excavator system is 4705 mm, the cutterhead torque is 354 kN m, the cutterhead speed is 2.3r/min, and the driving power is 30× 3 kW. The stroke of the correcting hydraulic cylinder is 85 mm, and the thrust of the correcting hydraulic cylinder is 980 kN×the total mass of the main engine (t). When the pipe jacking machine jacked 200 m of pipes, the deviation correction system failed, and the deviation correction action could not be produced, so that the construction could not be carried out.

1. The deviation correction system does not work

A Φ1 800 mm muddy water pressurized pipe jacking machine (expandable to 2000mm), the total length of the rotary excavator system is 4705 mm, the cutterhead torque is 354 kN m, the cutterhead speed is 2.3r/min, and the driving power is 30× 3 kW. The stroke of the correcting hydraulic cylinder is 85 mm, and the thrust of the correcting hydraulic cylinder is 980 kN×the total mass of the main engine (t). When the pipe jacking machine jacked 200 m of pipes, the deviation correction system failed, and the deviation correction action could not be produced, so that the construction could not be carried out.

The deviation correction system of the rotary excavation system of the pipe jacking machine adopts an electro-hydraulic integrated operating system, which consists of a hydraulic oil tank, an oil filter, an oil inlet filter, an electric motor, a hydraulic pump, a one-way valve, an overflow valve, a pressure gauge, an electromagnetic Reversing valve, hydraulic lock, overload relief valve, electromagnetic reversing valve for mud tank, mud tank door overflow valve, correction hydraulic cylinder and other components.

The hydraulic pump transmits the hydraulic oil to the control valve, and transmits it to the deviation correction hydraulic cylinder according to the required deviation correction. However, since the working pressure of the deviation correction hydraulic cylinder cannot reach the required 20 MPa (only 16 MPa), the system pressure is low. The deviation correction hydraulic cylinder cannot perform normal deviation correction operation.

The reasons for the low pressure of the correcting hydraulic system are as follows: the overflow valve fails; the electromagnetic reversing valve is severely worn, resulting in internal leakage; internal leakage of the correcting hydraulic cylinder; the oil inlet filter is blocked; the power of the hydraulic pump is reduced.

According to the analysis results, adjusting the pressure of the relief valve has no obvious effect; using the transposition method to replace the relief valve of the same type in other parts for debugging also has no effect, indicating that the relief valve is good. Check the electromagnetic reversing valve, no oil leakage, loose valve core and unclear gear position are found, indicating that the electromagnetic reversing valve is also good. The pressure test of the deviation correction hydraulic cylinder was carried out, and the pressure was normal, and no internal leakage was found. The oil inlet filter was removed and checked, no clogging was found. Finally, it is judged that the power drop of the hydraulic pump is the main cause of the failure.

Stop the deviation correction hydraulic system, cut off the power supply, remove the hydraulic pump from the fuel tank, replace the hydraulic pump of the same type, and run the test machine. The system pressure can reach 26 MPa, and the deviation correction operation works normally.

2. The deviation correction system cannot correct deviation to the left

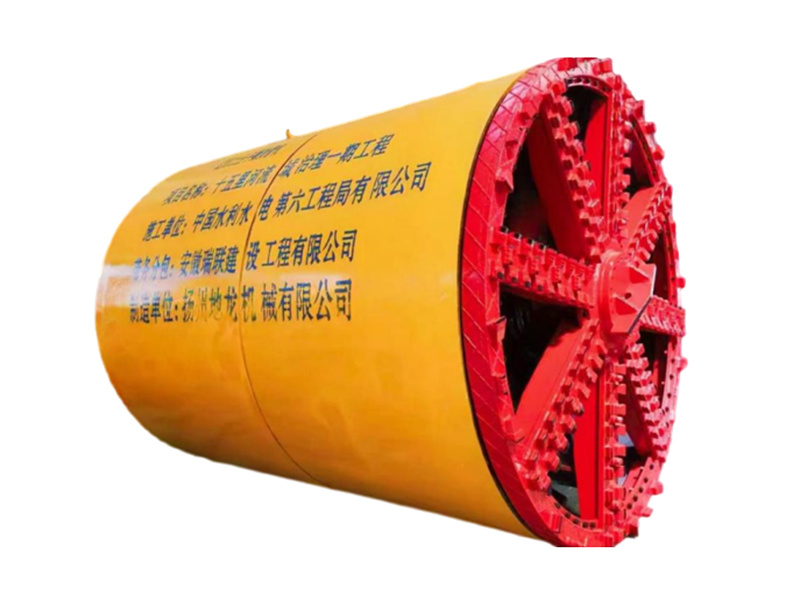

A Φ2000mm earth pressure balance pipe jacking machine, after overhauling the electrical operation, hydraulic pressure and soil discharge and other systems, during the all-round adjustment and test machine process, it was found that the deviation correction system of the rotary excavation system did not move to the left, and other directions were normal.

首先采用换位法将左面与右面的电磁换向阀进行换位,结果还是左面不能纠偏。再将左面与右面的液压缸进行换位调试,仍然是左面不能纠偏。通过以上换位调试,说明纠偏系统的液压回路良好。继续排查时,把旋转挖掘系统的前端摆动部分与后端随动部分解体分开,发现前钢壳与后钢壳连接处的管道防水胶圈老化变形,影响纠偏系统向左面动作。

更换了前钢壳与后钢壳连接处老化变形的管道防水胶圈,试机后纠偏系统向左面动作正常。

3、液压泵站换向阀失灵

在污水管道施工中,顶管机的液压泵站在连续工作1 h之后,换向阀不能按要求顺利换向,时好时坏。

这台液压泵站的液压回路比较简单,采用的是4WE16G/EW220型电磁换向阀,当工作1 h之后,电磁阀就发热,不能正常换向。

拆下电磁换向阀,测绘电磁换向阀底座,参照底座尺寸查找到一种型号为4WMM16G50的手动换向阀,安装后工作正常。

4、螺旋泥土输送机减速器箱体内进泥土

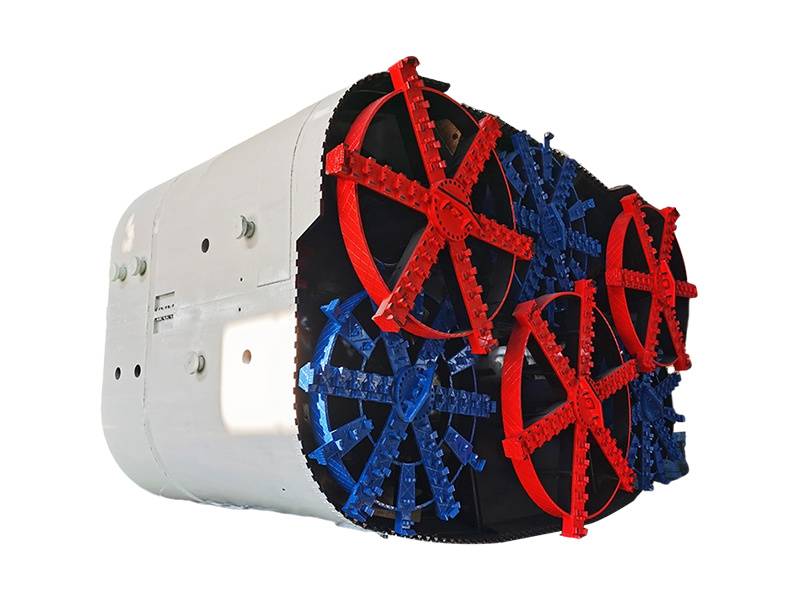

一台Φ3 000 mm土压平衡顶管机,承担顶进Φ3 000mm钢管、全长1 km 的工程施工任务。旋转挖掘系统掘进到800 m 时,发现螺旋泥土输送机的减速器箱体内有泥土。

造成这一故障有2种原因:一是螺旋轴轴颈的密封环严重磨损,轴颈密封不良,导致泥土从螺旋轴轴颈处进入减速器箱体内;二是由于螺旋泥土输送机土压大于减速器箱体内压力,导致泥土进入减速器箱体内。但是螺旋轴轴颈的密封环是施工前才更换的新件,不会磨损那么快。因此土压大于减速器箱体内压力为故障主要原因。经了解,操作人员在开机掘进时,没有把泥土舱闸门打开,所以泥土舱压力过高,最终导致泥土进入减速器箱体内。

There are two steps to eliminate this fault. The first step: remove the oil drain plug of the reducer, start the motor of the screw soil conveyor, and discharge the soil in the reducer box from the oil discharge port. After a part of the soil is discharged, add hyperbolic gear oil from the filling port, and then start the motor of the screw soil conveyor to fully mix the soil in the reducer box with the gear oil, and then discharge it from the oil discharge port. This cycle works until the soil in the reducer box is exhausted. Step 2: After the soil in the reducer box is exhausted, add diesel oil into the reducer box to clean the reducer gears. After cleaning, add hyperbolic gear oil according to the standard amount.

Label: