Construction equipment for pipe jacking

Release time:

2020-09-14

According to the method of excavation and soil balance, it can be divided into: manual excavation roadheader, extrusion roadheader, air pressure balance roadheader, mud-water balance roadheader, and earth pressure balance roadheader.

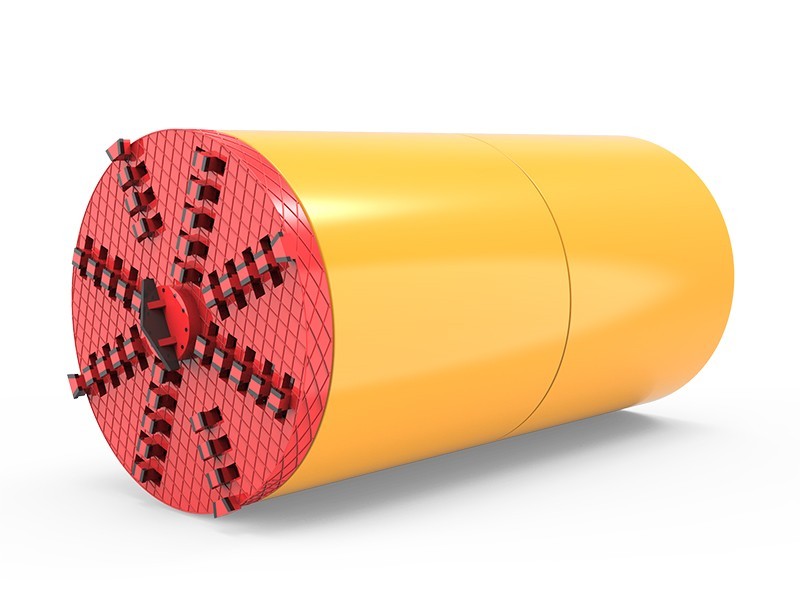

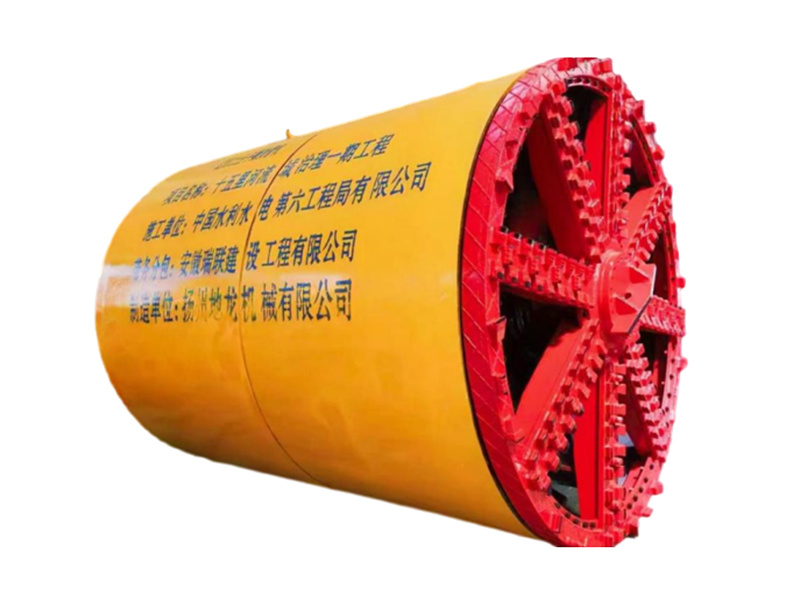

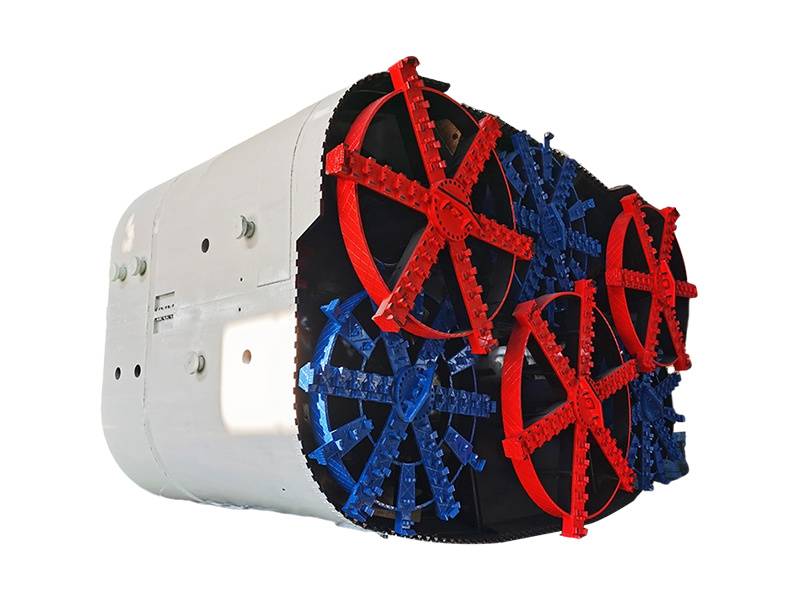

1. Tunneling machine

According to the method of excavation and soil balance, it can be divided into: manual excavation roadheader, extrusion roadheader, air pressure balance roadheader, mud-water balance roadheader, and earth pressure balance roadheader.

Tool pipe: The mud-water balance pipe jacking machine without cutter head is also called tool pipe, which is the key equipment for pipe jacking. It is installed at the front end of the pipe, and its shape is similar to that of the pipe.

Functions: breaking ground, orienting, rectifying, preventing landslides, and discharging mud.

Composition: mud flushing bin (front), operating room (middle), control room (rear) with horizontal hinges and up and down correcting oil cylinders to adjust the up and down directions (ie slope), vertical hinges and horizontal correcting oil cylinders to adjust left and right directions (horizontal curves ) ), mud ring, control room, left and right adjustment oil cylinder, up and down adjustment oil cylinder, operation room, suction pipe, flushing mud bin, grid, tool pipe structure

2. Jacking equipment

Main jacking system - main oil cylinder: 2~8 pieces, stroke 1~1.5m, jacking force 300~1000t/piece;

The jacking force of a single jack should not be too large: jack, pipe section, backseat material.

Main oil pump: 32-45-50MPa; console, high-pressure oil pipe.

Top iron: make up for insufficient cylinder stroke, thickness < cylinder stroke

Guide rail: top tube guide

Relay room - relay oil cylinder, relay oil pump or main oil pump.

3. Engineering tube

The main body of the pipeline is generally circular, with a diameter of 1.5-3m. Length 2-4m.

China Pipe Material Types

Reinforced concrete pipe: above C50, the most widely used, used in short-distance sewers;

Steel pipe: the second place in the list of applications, used for long-distance pipe jacking such as tap water, gas, and natural gas;

Steel pipe, reinforced concrete composite pipe: outer steel and inner concrete, used for super long-distance jacking;

Steel pipe, plastic composite pipe: outer steel and inner plastic, used for transporting strong acid liquid and high-purity water.

4. Dumping equipment

Manual excavation - when digging the soil manually.

Screw conveyor - earth pressure balance pipe jacking machine.

Mud suction and mud discharge equipment - mud water balance, mud water aerated balance pipe jacking machine.

5. Relay ring

pipe jacking resistance

Front - no change

Side friction force—as the jacking distance increases, it is obvious that the long-distance pipe jacking is divided into several sections, and relay rings are set between the sections. The relay jacking equipment can make the subsequent section only overcome the side friction force of the jacking pipe section. Can. Start the relay ring oil cylinder in sequence from front to back, and the jacking pipeline can realize long-distance jacking.

Relay ring—Arrange several relay cylinders in a ring in the relay ring, and the stroke of the cylinder is 200mm.

When the relay ring oil cylinder works, the pipe section behind becomes the back seat, pushing the adjacent pipe section in front to the front, and overcomes the side friction force in sections.

Label: