Main jacking cylinder, guiding (correction) cylinder, intermediate cylinder for pipe jacking

Release time:

2020-09-10

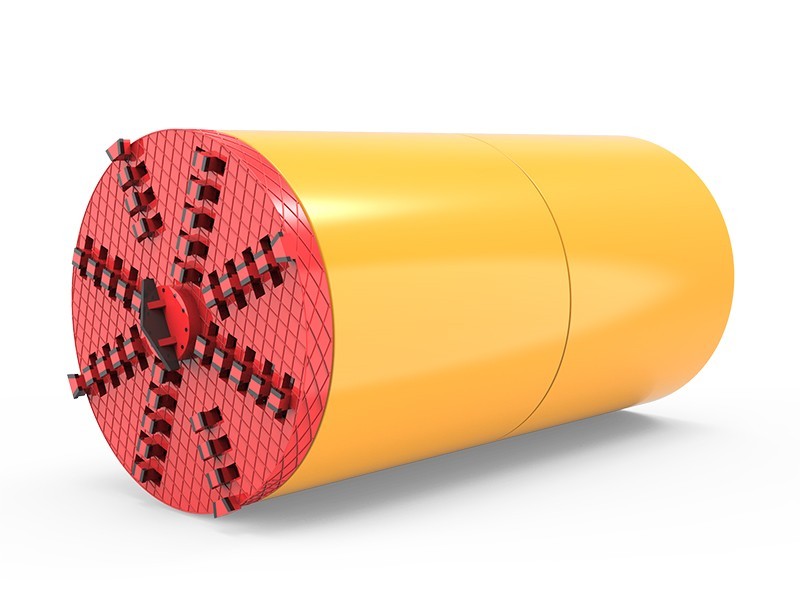

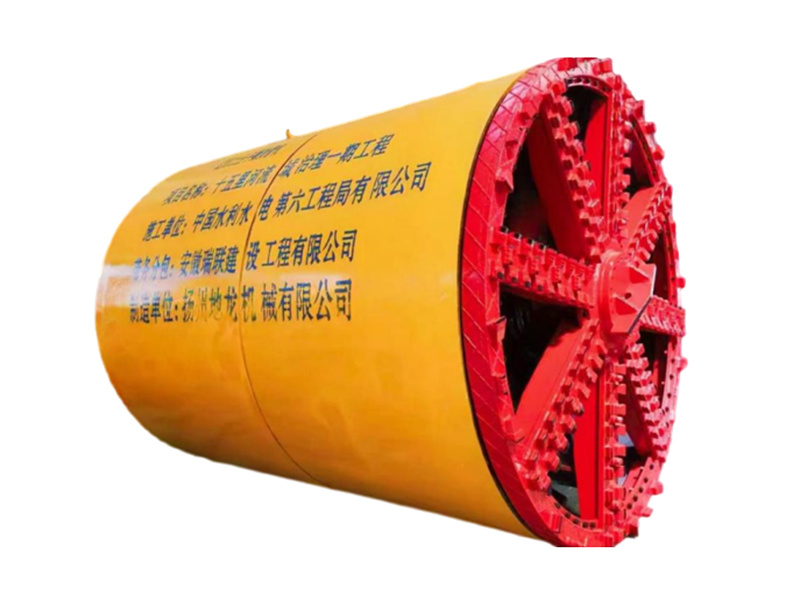

The main jacking cylinder is installed in the jacking pit and is used to jack the pipeline into the soil, and its form is mostly a hydraulically driven piston double-acting cylinder. The characteristic of this double-acting cylinder is that it can be extended or retracted; most of the main top cylinders used today are double-acting cylinders

1. Main top oil cylinder

The main jacking cylinder is installed in the jacking pit and is used to jack the pipeline into the soil, and its form is mostly a hydraulically driven piston double-acting cylinder. The characteristic of this double-acting cylinder is that it can be extended or retracted; most of the main top cylinders used today are double-acting cylinders, and the most typical ones are double-acting cylinders. This double-acting jacking cylinder is mainly composed of six major parts: cylinder body, piston, piston rod, guide sleeve, seal and sliding shoe. Among them, the cylinder body is the main part of the jack, which must have sufficient wear resistance and pressure resistance. Most of its materials are 45# seamless steel pipes, and can also be made of forged steel and cast steel. Generally, the cylinder body needs to be completed through multiple processes such as turning, boring, rolling, heat treatment, etc., and the processing precision requirements are relatively high.

Most of the pistons are made of ductile iron and copper alloy. There are two types of piston rods: hollow and solid, generally made of forged 45# steel.

The guide sleeve is a circular ring that acts as a guide when the piston reciprocates. It is fixed on the front edge of the cylinder body, and the surface is in close contact with the surface of the piston rod. It must have good wear resistance and high strength. Generally, it is used Made of high quality copper alloy.

Since the jack is a closed pressure vessel, the moving part of the piston, the static part between the end cover and the cylinder need to be reliably sealed. There are various types of seals. Static seals often use "O"-shaped rubber seals, while dynamic seals generally use "U", "V", and "L"-shaped seals.

The equal-thrust main jack cylinder is a new type of secondary cylinder. Its characteristic is that the thrust of the first stage and the second stage are equal, and the stroke of the second stage oil cylinder is the same and longer. Pipe jacking construction adopts this kind of oil cylinder, which can greatly improve the efficiency and safety of pipe jacking construction without adding additional jacking iron to increase the stroke.

The power unit of the jacking equipment (such as hydraulic workstation, etc.) and the jacking equipment are usually separated, but sometimes they can be integrated together. In the layout of jacking equipment in pipe jacking construction, the number of jacking cylinders can be any number greater than 2. The total jacking capacity of the jacking cylinders is related to the bearing capacity of the jacking pipe section. At the same time, it should also be considered in the larger There is a certain safety margin under the condition of initial jacking force. When jacking box-type pipe sections, the number of jacks can sometimes reach 20 sets, and the total jacking capacity can reach several thousand tons.

During the pipeline jacking process, continuous jacking force can be applied by two-stage or three-stage telescopic cylinders. The maximum stroke of this cylinder can reach 4000mm, which is suitable for most pipeline jacking. This oil cylinder is usually fixed on the back seat of the working well, and its base part is quite long, and also needs a longer working well when it is retracted.

The second jacking method, the jacking frame is equipped with a short-stroke oil cylinder (the stroke is only 300mm), however, the jacking frame can move along its lower base, and can be locked in place by a suitable groove pin device. on the base. After each jacking stroke is completed, release the jacking frame and move it forward, then lock it again to jack up the next stroke.

The third jacking method is to keep the position of the jacking cylinder unchanged, and use concrete or steel pads to extend the jacking length after each jacking stroke. When multiple pads are used, in order to avoid danger, corresponding locking measures should be adopted for the pads.

In addition to the above-mentioned jacking method, there is also a main jacking device composed of a combined oil cylinder. Multiple oil cylinders work together on a steel back plate to ensure that the jacking force is evenly transmitted to the back seat wall; in addition, the pressure equalizing ring at the front can also distribute the pressure evenly on the end surface of the jacking pipe , it is required that the structure and shape of the pressure equalizing ring match the end face of the pipeline. At the same time, the thrust cylinder and the pressure equalizing ring are connected by a spherical hinge, which is also conducive to the uniform transmission of jacking force.

2. Guidance (correction) cylinder

The guide cylinder is installed behind the first pipe or tool pipe to adjust the deviation of elevation and axis. The stroke of the guide cylinder is generally 50~100mm, and the jacking force is 500~1000kN. During construction, the tonnage value of the guide cylinder should be selected according to the pipe diameter, jacking method, tool pipe length, geological conditions and other factors. Figure 4-5 shows the structure of the guide cylinder. In order to adapt to the change of the angle of the tool tube during deviation correction, the surfaces at both ends of the guide cylinder are not parallel. In order to avoid the eccentric force on the guide cylinder, consider that one end of the jack is hinged and the other end is a spherical surface, which can be adjusted by itself, so that the guide cylinder can bear axial pressure to ensure good working conditions for the guide cylinder.

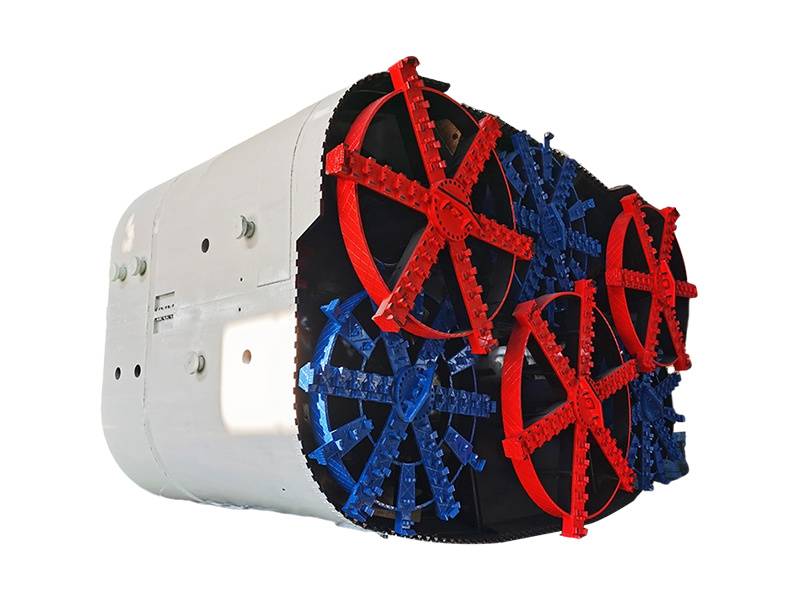

3. Relay station oil cylinder

The oil cylinder of the relay station is installed in the middle of the jacking pipeline as a relay jacking tool, and it is also a piston-type, double-acting jack. However, the stroke is shorter than that of the main top cylinder to avoid excessive length between relays. The tonnage depends on the installation position of the relay room in the jacking pipeline. According to the working performance of the relay station, it is best to arrange the oil cylinders of the relay station evenly to achieve the purpose of uniformly applying the jacking force. The capacity of the relay station oil cylinder is generally not greater than 1000kN, and it is required to have as many sets as possible with a small tonnage and arrange them evenly in the circumferential direction.

Label: